Technology

CORE TECHNOLOGY APPLICATIONS

The Problem

Cyanide is the leading gold extraction agent. It is effective and low cost, but it is a toxic chemical that creates significant environmental risk for mine operators and local communities. It is increasingly opposed by many communities, NGO’s, governments, agencies and investors.

Other miners produce gold concentrates that are shipped to smelters for processing. Payment times are lengthy, shipping and logistics costs are considerable, processing costs are high.

Environmental and carbon footprint of both existing processes are high.

Our Solution

EnviroMetal’s chemistry formulations recover gold from gravity and flotation concentrates with similar effectiveness and costs to cyanide. We allow concentrate producers to recover gold doré on site. We help gold producers reduce processing costs and environmental footprints in many cases.

“We help gold producers reduce processing costs and environmental footprints in many cases.”

EnviroMetal’s Advantages

COMPETITIVE

• Gold recovery rates comparable to cyanide

• Leach kinetics comparable to cyanide

• Chemical costs comparable to cyanide

• Costs vs shipping concentrates to downstream smelters

REDUCED

• Reliance on smelters

• Environmental footprint

• Permitting, monitoring and remediation costs

• Water usage – no water effluent

IMPROVED

• Access to environmentally sensitive areas

• Operator sustainability and CSR profile

• Stakeholder support of mining projects

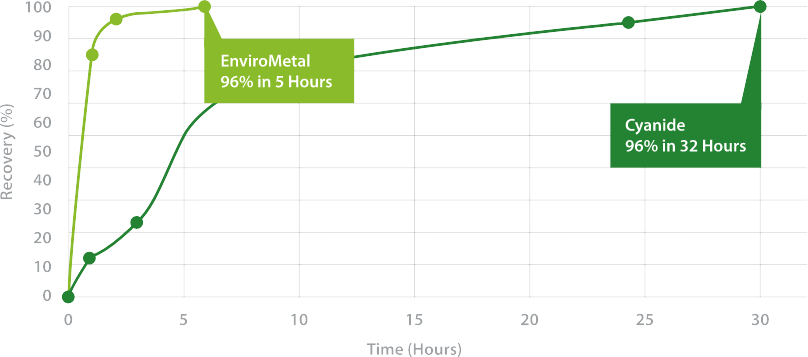

How we compare

EnviroMetal Gold Recovery vs Cyanide

Independent testing completed by SGS

Gold Mining Business Model

EnviroMetal has little or no competition in the mining sector for economic, sustainable alternatives to cyanide.

We also offer significant value to gold miners who produce concentrate materials, but who would prefer to recover gold on-site rather than incur costs for downstream processing. Our technical advantages and early mover status in this market position us as to be a dominant player.

EnviroMetal’s gold sector strategy is based on a licensing and royalty model.